Home10 production steps

10 production steps

on Colltex ski skins

**01 I** The base material (mohair/granules) is spun into yarn.

**01 I** The yarn is thereupon woven into a double weave on the loom and separated into a base and top weave.

**01 I** The pile fabric is thoroughly rinsed, dyed, or printed on.

**01 I** Colltex is the only manufacturer to use the additional Colltex Edge coating. This coating adjusts the torsional strength of the pile and prevents the ski skin from fraying.

**01 I** The backing fabric (back of the ski skin) made of cotton and polyester is woven and made impervious to shrinkage.

**01 I** The pile fabric (pile side) is pressed together with the backing fabric using both pressure and heat and by means of an inserted film.

**01 I** After the Colltex Drybase the backing oft he ski skin is coated with our proven hotmelt resin adhesive.

**01 I** On the cutting table, the ski skins are now cut to size on the CAD-controlled cutting table to precisely fi t the ski model.

**01 I** Now the matching front and tail hook are sewn to the ski skin.

**01 I** After a final check, the ski skin is packed and shipped together with a Colltex tote bag, the protective net, and instructions.

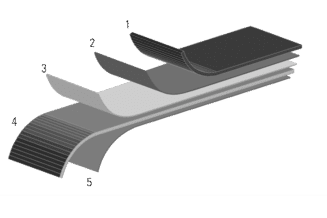

1. Fabric pile + pile base fabric

2. Colltex Edge

3. Waterproof lamination

4. Back cloth with Colltex Drybase

5. Colltex hotmelt coating